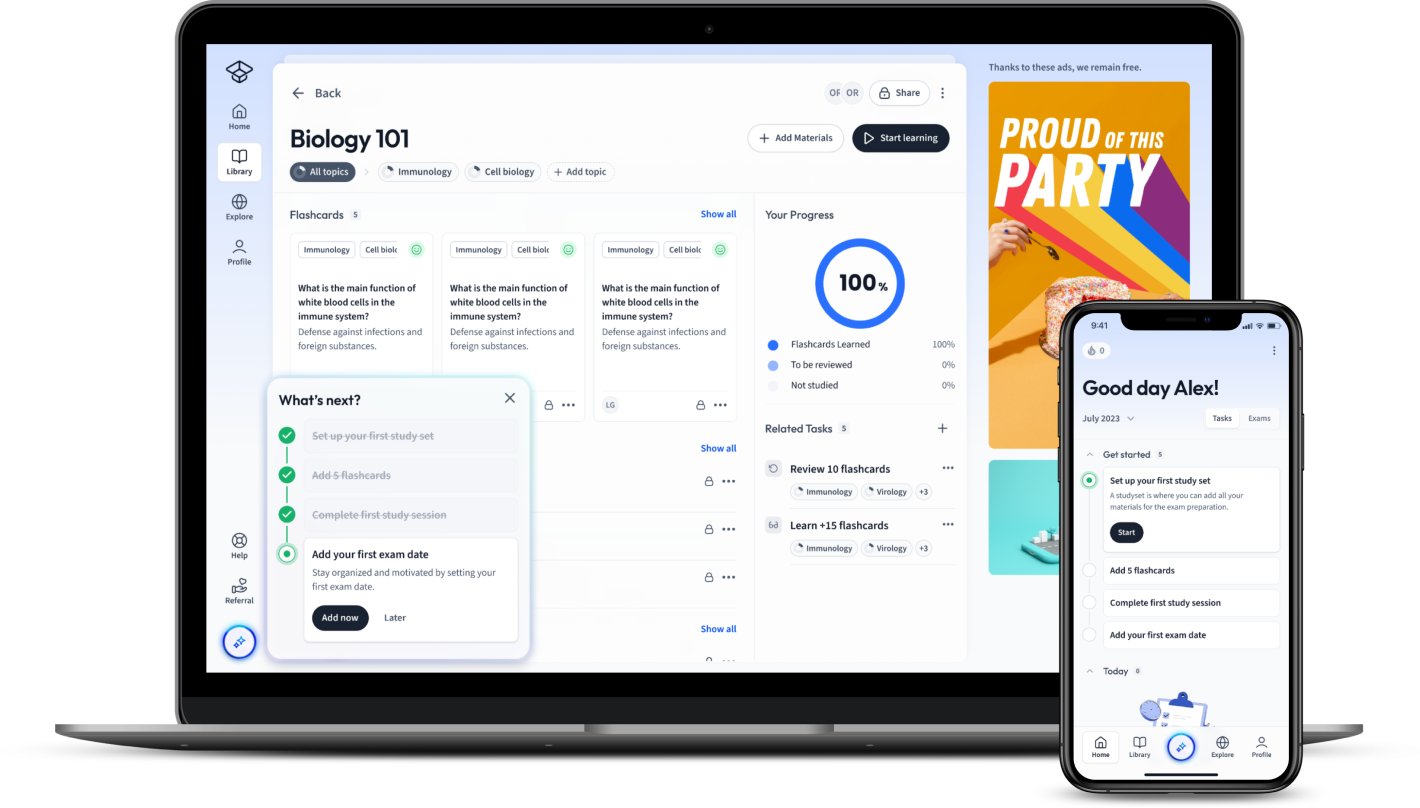

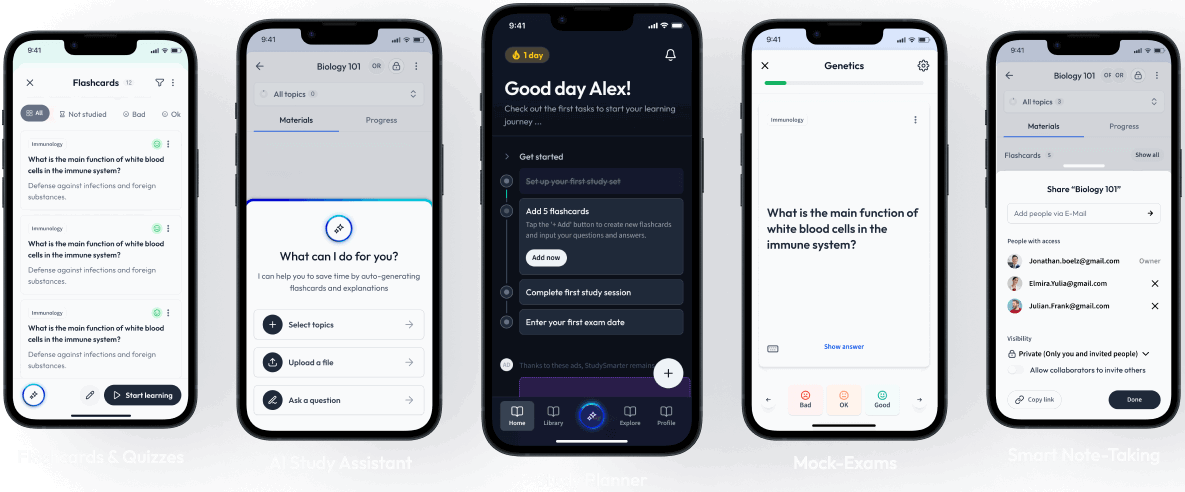

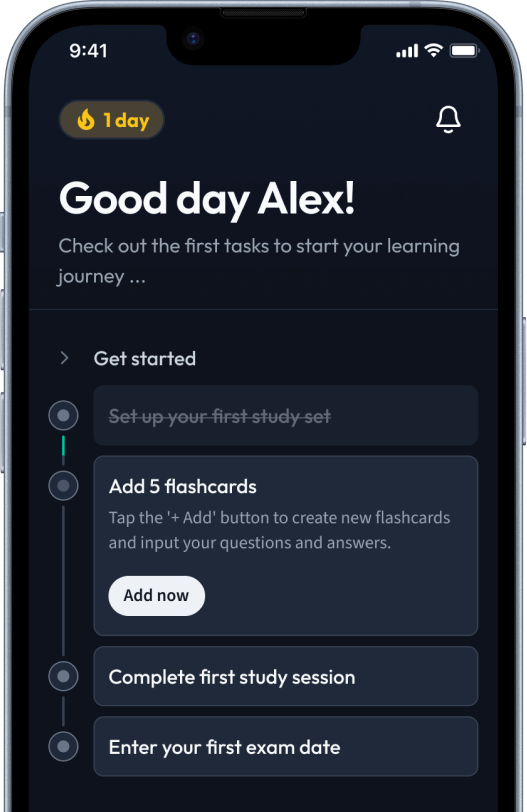

StudySmarter: Study help & AI tools

4.5 • +22k Ratings

More than 22 Million Downloads

Free

Lerne mit deinen Freunden und bleibe auf dem richtigen Kurs mit deinen persönlichen Lernstatistiken

Jetzt kostenlos anmeldenThe more inventory a company has, the less likely they will have what they need."

- Taiichi Ohno

To understand what Taiichi Ohno meant by this statement, let's examine what inventory is exactly, how it can be managed and discuss why he was concerned by companies holding too much inventory.

Inventory management is the management of goods held by a company.

Inventory is a stock of goods that is recorded under the current asset on the company's balance sheet.

Typically, there are three types of inventory.

1. Raw materials or components: stock purchased from suppliers and are to be used in manufacturing.

Wood and screws to make a table.

2. Work in progress: semi or partially-finished goods.

A table leg made from a piece of wood.

3. Finished goods: finished goods ready for distribution.

A complete table to be sold in a furniture store.

Let's take a look at why companies might decide to hold inventory.

The lack of raw materials not only slows down production but also affects other stages of the supply chain. Limited supplies could lead to products not being finished on time, which may result in the cancellation of orders and loss of sales. Keeping stock can prevent this by making sure materials needed are available at all times.

Having inventory in stock allows the company to keep the production going while waiting for new materials to arrive. Safety stock can provide a buffer for events such as natural disasters or loss of goods.

Suppliers tend to offer discounts for a large number of goods. By buying in bulk, the company can take advantage of lower prices, which reduces the amount that customers have to pay for the final products. However, the high level of inventory will result in more expensive storage and maintenance.

The demand for goods is not consistent but fluctuates wildly over the year. For example, special occasions such as Christmas, Valentine's, and Halloween may ramp up the demand for certain goods. Keeping inventory allows businesses to meet customer needs during the high seasons. The key is to make the right order amount to avoid excess stock storage.

There are three main types of inventory cost:

These are costs for ordering goods. For example, administrative costs, inspection costs, cost of placing an order with a supplier.1

To minimize the ordering costs, a company can calculate EOQ (Economic Order Quantity) - an optimal order quantity at the lowest total costs.

These are costs associated with inventory unsold, including2:

Opportunity costs: This is the money that could be invested elsewhere if not used in inventory. For example, if you invest £10,000 in warehousing, you couldn't use it to purchase new office furniture.

Storage costs: These are costs for storing physical inventory. For example, warehousing, storage rents, utilities, insurance. An increase in inventory comes with a higher storage cost.

Wages: These are the salaries you pay for employees who work at the warehouse and fulfil the order.

Depreciation costs: These are costs incurred as the value of your inventory appreciates over time. For example, products become obsolete.

These are costs that incur when inventory goes out. For example, a loss of sales due to unfulfilled orders and overnight shipping fees to acquire inventory that is not available.

Inventory planning is an important aspect of the supply chain since it controls the level of inventory held. This allows the company to keep up with its production and meet customer needs while safeguarding against the loss of goods or late deliveries by the suppliers.

Planning and controlling inventory is also tied with the company's working capital - the money used to pay for short-term expenses (within a year). If the business spends too much money on holding inventory, it may not have enough capital for other business activities. To balance the working capital, companies must order the right amount of stock at the right time. Thus, the primary objective of inventory control is to minimize inventory costs.

An inventory control chart is an efficient tool for managing stock levels and minimizing inventory costs (see Figure 1 below).

Figure 1. Inventory Control Chart, StudySmarter

Figure 1. Inventory Control Chart, StudySmarter

The components of the inventory control chart:

Having the right level of inventory is important as it allows the company to keep up with the production while waiting for new materials to arrive. Reserved inventory also serves as a buffer for unpredictable events such as natural disasters or economic crises.

Here are some factors influencing the level of stock:

1. Wikiaccounting, Ordering Cost: Definition, Formula, Example, and How Does It Work, 2022

2. Shannon Callarman, What Is Inventory Holding Cost? The Price for Ecommerce Storage, 2020

Inventory is a stock of goods that is recorded under the current asset on the company's balance sheet.

Product & vendor information, good relations with suppliers, organized inventory and optimal reorder levels.

Inventory helps a business by ensuring:

efficient production, protection against late deliveries, cost reduction, and meeting unexpected demands.

Yes, inventory is a current asset.

The purpose of the inventory is to ensure a non-stop supply of materials in production.

What is inventory?

Inventory is the stock of goods by a company.

What is not a type of inventory?

Machine to produce the products

Why do companies store inventory?

Suppliers typically offer discounts to companies who buy their products in bulk. By ordering a larger quantity, the company can benefit from a better buying cost. This transfers to lower prices and helps the company to gain a competitive advantage in the market.

What happens if the company keeps too much stock?

Excessive storage costs.

What is working capital?

Working capital is the money used to pay for short-term expenses (within a year) such as inventory, short-term debts, and day-to-day operations.

How does customer demand affect the level of inventory?

The demand can be unexpected or seasonal

Unfulfillment of the demand can cost the company dearly.

Already have an account? Log in

Open in AppThe first learning app that truly has everything you need to ace your exams in one place

Sign up to highlight and take notes. It’s 100% free.

Save explanations to your personalised space and access them anytime, anywhere!

Sign up with Email Sign up with AppleBy signing up, you agree to the Terms and Conditions and the Privacy Policy of StudySmarter.

Already have an account? Log in