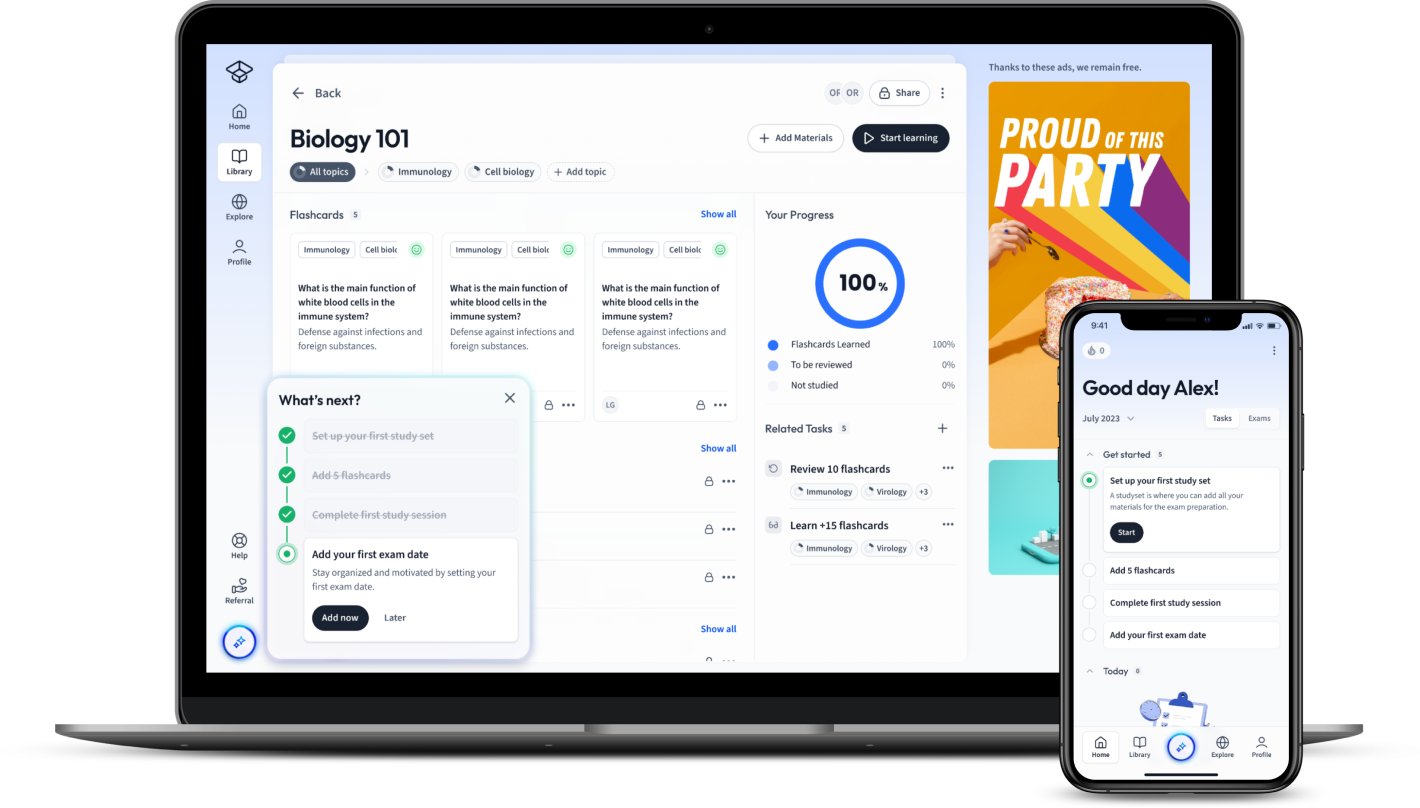

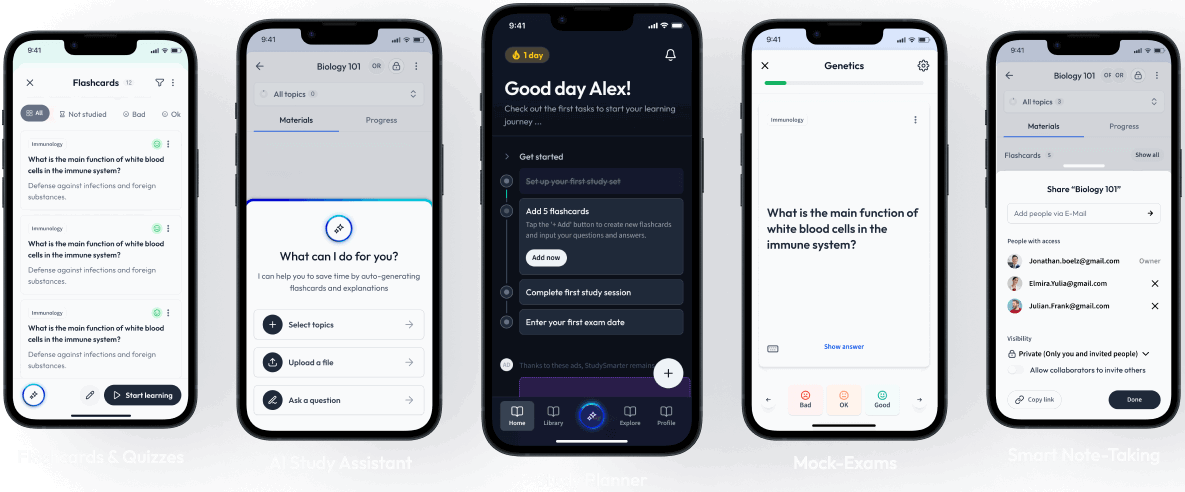

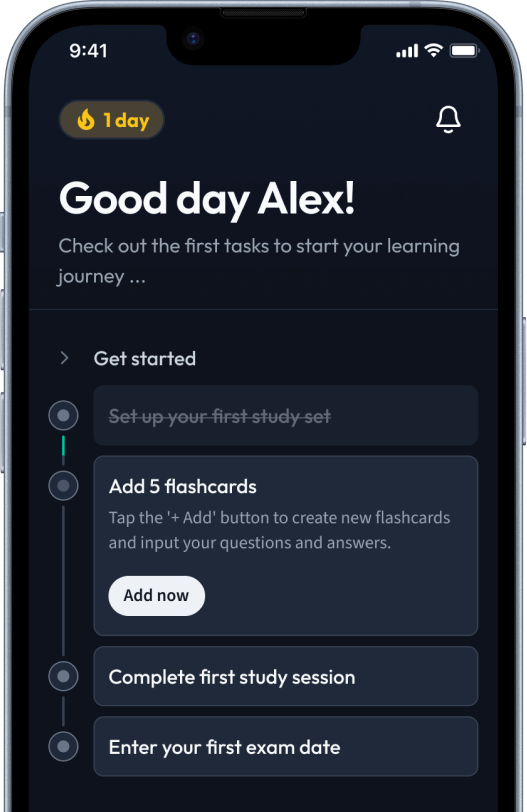

StudySmarter: Study help & AI tools

4.5 • +22k Ratings

More than 22 Million Downloads

Free

Delve deep into the world of business acumen by enhancing your knowledge on improving the supply chain. This comprehensive guide offers insights into why improvement in this area is paramount for successful operations, whilst shedding light on effective strategies and techniques for supply chain optimisation. You will navigate through real-world examples, understand future trends and explore the role of technological advancements in this field. Embark on this enlightening journey to aid in boosting your business outcome and operational efficiency through strategic supply chain improvements.

Lerne mit deinen Freunden und bleibe auf dem richtigen Kurs mit deinen persönlichen Lernstatistiken

Jetzt kostenlos anmeldenDelve deep into the world of business acumen by enhancing your knowledge on improving the supply chain. This comprehensive guide offers insights into why improvement in this area is paramount for successful operations, whilst shedding light on effective strategies and techniques for supply chain optimisation. You will navigate through real-world examples, understand future trends and explore the role of technological advancements in this field. Embark on this enlightening journey to aid in boosting your business outcome and operational efficiency through strategic supply chain improvements.

Every business, regardless of its size, relies considerably on its supply chain. The term 'Supply Chain' refers to the network of companies co-operating to create and deliver a product or service to the end customer.

A supply chain starts with the delivery of raw material from a supplier to a manufacturer, and ends with the delivery of the finished product or service to the end consumer. Thus, 'improving the Supply Chain' implies enhancing this network's efficiency and efficacy.

The supply chain plays a crucial role in business operations by determining the flow of goods and services from the point of origin to the point of consumption. Efficient supply chain management is a vital component for companies to gain a competitive edge in the marketplace.

| Factors of Supply Chain Success | Explanation |

| Cost Efficiency | Reduced costs lead to improved profit margins |

| Time Efficiency | Saves time on delivery, production, and cycle time |

| Flexibility | Ability to adapt to changes in demand quickly |

Consider a clothing retailer, for example. They might have a highly efficient supply chain if they can swiftly move clothes from the design phase, through manufacturing, and into stores in response to changing fashion trends, all while minimising costs.

Improving the supply chain can significantly impact a business’s profitability and growth.

According to a report by McKinsey, companies with efficient supply chains tend to have 15% lower operating expenses, less than half the inventory holdings, and more than three times faster cash-to-cash cycles than others.

By streamlining supply chain processes, you can reduce costs, improve service quality, and enhance customer satisfaction.

The importance of improving the supply chain cannot be overstated and here's why:

In conclusion, deciphering how to streamline the supply chain is an essential aspect of a company's strategic planning. By making these improvements, a company can not only boost its bottom line, but also improve its customer satisfaction and brand reputation.

Improving the supply chain is a comprehensive process that involves conceptualising and implementing strategies which would enhance the overall supply chain's efficiency and effectiveness. The scope is not just confined to standardising operations but extends to innovating new approaches that could set the trend in supply chain management.

Supply Chain Improvement Strategies refers to the systematic approach that identifies and introduces changes to enhance a business's supply chain in terms of cost, speed, reliability, and sustainability.

There is an array of strategies that could be implemented to enhance supply chain performance. Let's explore them in considerable detail.

Amazon, the global e-commerce giant, is a stellar example of successful implementation of supply chain improvement strategies. From running fully automated warehouses to using drones for deliveries, Amazon has redefined supply chain effectiveness via continuous innovation and adoption of sophisticated technologies.

Improving reliability in the supply chain can bridge the gap between expectation and reality in supply chain management. Various strategies can be undertaken for the same.

According to a survey by Deloitte, 79% of organisations with superior supply chain capabilities report significantly above-average revenue growth. They mention strong supplier relationships and technological adoption as key contributors to their supply chain's reliability.

Being innovative in conceiving supply chain improvement strategies is key to stay ahead in the competitive world. Here are few innovative strategies that companies are incorporating today.

One such innovative company is VeChain, which adopts blockchain technology to provide end-to-end supply chain solutions. It helps in tracking the quality and authenticity of products along the supply chain, providing a new level of transparency and efficiency.

The continual drive for efficiency and risk mitigation has made supply chain optimisation an area of growing interest. Exploring these techniques is an essential step towards maintaining a lean, efficient, and effective supply chain that drives business growth.

From processing orders and managing inventory to overseeing logistics and procurement, boosting the supply chain's efficiency necessitates the adoption of specific instruments. These tools provide operational excellence, thereby accelerating the pace at which the supply chain functions.

Artificial Intelligence (AI) involves the simulation of human intelligence in machines programmed to think like humans. Machine Learning, a subset of AI, gives computers the ability to learn from and interpret data without being explicitly programmed.

As per a survey by Gartner, by 2023, over 50% of global product-centric midsize and enterprises will have invested in real-time transportation visibility solutions. Such cutting-edge technology implementation dramatically enhances supply chain efficiency.

Choosing the right suppliers acts as a linchpin in the supply chain. Gratifying quality, cost, capacity, and stability are some of the crucial factors you need to consider.

An instance of impeccable supplier choice is Apple's strategic partnership with Corning Incorporated for supplying gorilla glass. The unprecedented quality, cost-competitiveness, and regular supply have played an integral role in Apple's success.

Incorporating certain strategies can dramatically improve the efficiency of the supply chain, leading to increased productivity and better profit margins.

Just-In-Time (JIT) is an inventory management technique aiming at producing or delivering goods just as they are needed, reducing inventory costs. Scrum and Kanban are Agile project management methods that focus on delivering the most value in the least time.

Toyota is a brilliant example of Successfully incorporating JIT and Lean Management into their supply chain, a move that significantly reduces waste, improves efficiency, and cuts costs.

In today's fast-paced business environment, gaining any advantage over competitors can make a significant difference. Applying the techniques and strategies of supply chain improvement in real-world scenarios is a critical element to achieving this edge.

When it comes to improving the supply chain processes, there are numerous successful examples across the industry spectrum. These examples give a clear indication of the potential benefits and outcomes companies can expect when they take steps to overhaul their existing supply chain processes.

| Company | Supply Chain Improvement Strategy | Result |

| Zara | Fast-fashion model and just-in-time manufacturing | Reduced lead time, lower inventory costs, and ability to react swiftly to changing trends |

| Walmart | Centralised inventory management and strategic vendor partnerships | Increased revenue due to improved in-store availability and decreased operating costs |

| Starbucks | Direct sourcing practice and fair-trade commitment | Improved supplier relationships, increased customer loyalty, and brand differentiation |

Just-In-Time manufacturing is a production model in which products are built to meet demand, not created in surplus or in advance of need. The process is mainly driven by forecasts of customer demand. Consequently, wastes from the inefficient use of resources are reduced.

Examining the success stories of businesses that have implemented supply chain improvement strategies can provide valuable insights and practical knowledge on what works and what pitfalls to avoid.

Procter & Gamble (P&G), a renowned multinational consumer goods company, was facing challenges in maintaining consistent service levels for their broad lines of products across numerous countries. To address this, P&G utilised digital technology to transform its supply chain. They integrated their enterprise resource planning (ERP) system in all their global branches, improving visibility and control over their manufacturing and distribution processes. With these enhancements, P&G improved its service levels from under 80% in the early 2000s to nearly 99.9% today, significantly increasing customer satisfaction and loyalty.

Another impressive success story is Dell, a computer technology company. Dell embraced a configure-to-order supply chain model, which allowed customers to customise their products at the time of purchase. This model drastically reduced Dell's inventory carrying cost, improved profitability, and ensured that the products delivered to customers were the latest versions with updated technology. This strategic change in their supply chain model played a significant role in making Dell one of the leading computer technology players globally.

These illustrative examples demonstrate the transformative potential of improving the supply chain, emphasising that a well-maintained and streamlined supply chain can be a significant factor propelling the business towards the path of success.

Improving the supply chain is an ongoing process, adapting and evolving to meet the dynamic business landscape's demands. Keeping an eye on future trends in supply chain improvement can provide businesses with useful insights for strategic planning and decision-making.

Today's highly globalised and competitive business environment puts a strong emphasis on disrupting existing patterns and adopting innovative strategies. This section presents a deep dive into some of the emerging trends and innovations that are shaping the future of supply chain improvement.

Blockchain technology is a decentralised and distributed digital ledger. It records transactions across multiple computers so that any involved record cannot be altered retroactively, without the alteration of all subsequent blocks.

The future of supply chains is projected to be marked by an increased focus on improving reliability and efficiency as customer expectations continue to rise. The use of real-time tracking systems to improve delivery predictability, adopting demand-driven planning strategies to minimise stockouts and overstocks, and leveraging Internet of Things (IoT) for enhanced inventory management are all part of this future trend.

Amazon is a stellar example of a company that has successfully harnessed the capabilities of IoT. The company deploys robots and drones in its warehouses for picking and packing. It also utilises sensors and RFID tags for real-time inventory tracking, significantly enhancing their supply chain's reliability and efficiency.

Technological advancements have been instrumental in ushering in innovation in the supply chain management field. From predictive analytics to automated warehouse operations, technology footprint is omnipresent. Here is how technology is changing the face of supply chain improvement.

Cyber-Physical Systems (CPS) are integrations of computation, networking, and physical processes. Embedded computers and networks monitor and control the physical processes with feedback loops where physical processes affect computations and vice versa.

DHL, a global logistics company, makes extensive use of technology to improve its supply chain. It uses machine learning algorithms to forecast air freight transit time delays. Furthermore, they utilise IoT for real-time tracking of shipments, ensuring a reliable, efficient, and seamless delivery process.

Provide a definition of a supply chain.

A supply chain is a complete sequence of activities involved in the production and distribution of a commodity. It involves transforming raw materials into finished products and delivering them to customers.

What are some influences on the choice of suppliers?

What is lead time?

Lead time - time between placing an order and receiving a delivery

What is JIT?

Just-in-time (JIT) is a production system which requires deliveries even multiple times a day so that products do not have to be held in stock.

What are the three key areas of improvement in the supply chain?

What is meant by flexibility and why is it valuable?

Flexibility relates to the ability of an organisation to change its operations. Owing to flexibility, production can be modified cost effectively, in a way that customised products are not much more expensive than mass-produced alternatives. Additionally, if a supplier is flexible, customers are willing to pay a higher price.

Already have an account? Log in

Open in AppThe first learning app that truly has everything you need to ace your exams in one place

Sign up to highlight and take notes. It’s 100% free.

Save explanations to your personalised space and access them anytime, anywhere!

Sign up with Email Sign up with AppleBy signing up, you agree to the Terms and Conditions and the Privacy Policy of StudySmarter.

Already have an account? Log in