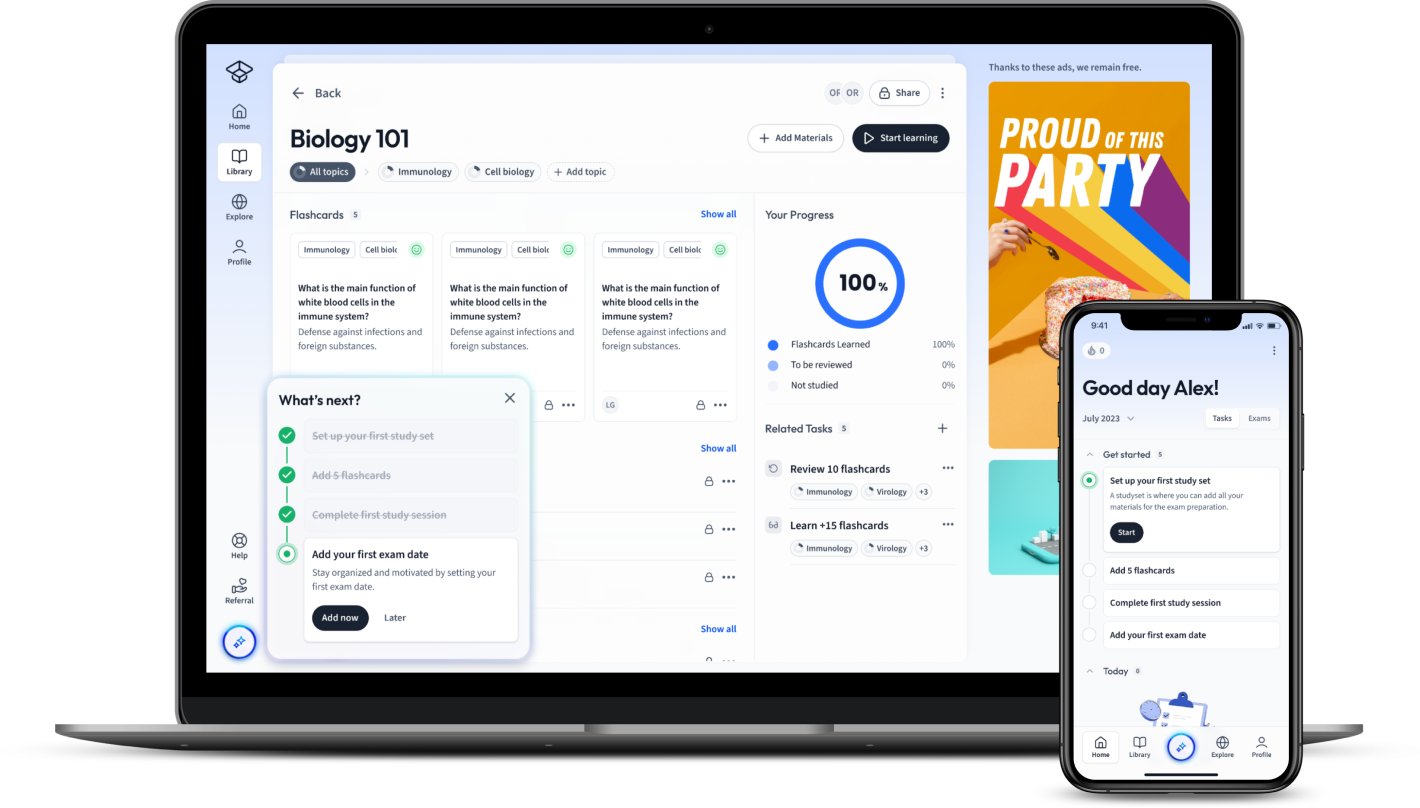

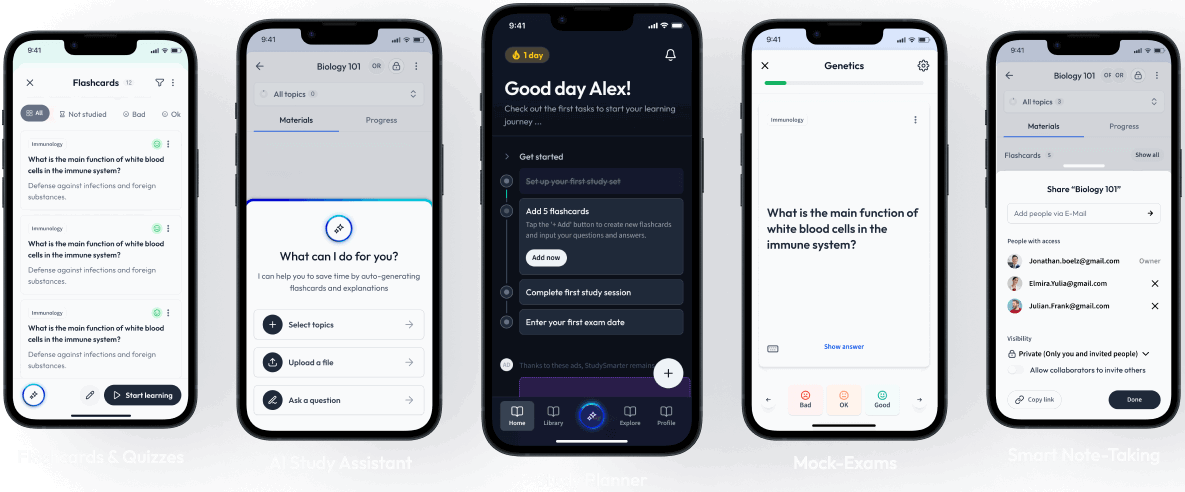

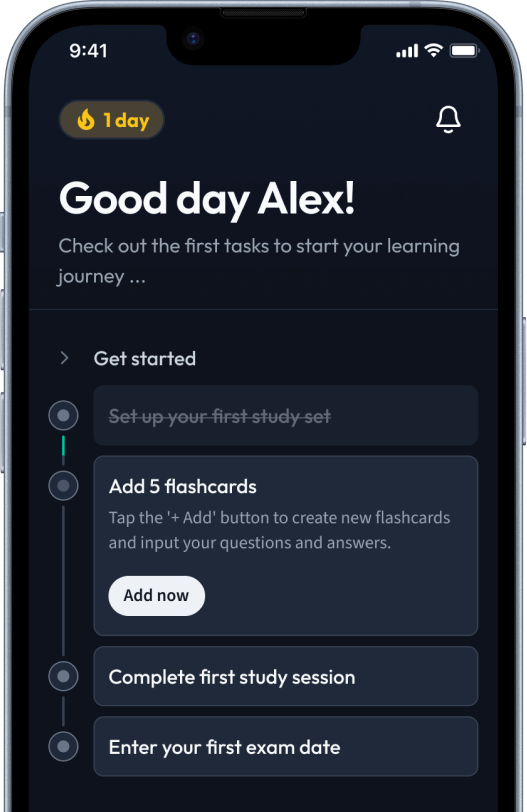

StudySmarter: Study help & AI tools

4.5 • +22k Ratings

More than 22 Million Downloads

Free

Lerne mit deinen Freunden und bleibe auf dem richtigen Kurs mit deinen persönlichen Lernstatistiken

Jetzt kostenlos anmeldenQuality is more important than quantity. One home run is much better than two doubles.”

– Steve Jobs

Measuring quality helps organisations to recognise weaknesses, highlights opportunities, and can be used to identify what works and what does not work to improve quality. Let's find out about the indicators that help identify quality for products and services!

Let's take a look at the types of indicators measuring quality.

Quality is a term commonly used by consumers, producers and supervisors. However, it is very general and denotes different things to different people. If two individuals describe a product as 'good quality', they might mean different things.

For instance, one individual likes the Toyota Corolla more than the Honda Civic. Another individual likes the Honda Civic more than the Toyota Corolla. But both individuals might not be comparing the two brands based on the same attributes. The first individual (who likes Toyota) may like its reliability, consistency, or after-sales service, which he considers superior to Honda. The second individual (who likes Honda) may prefer its attributes, luxurious look or its comfort.

The quality of any product can be catalogued into distinctive groups:

Performance: the operating characteristics of any product are generally quantifiable. For example, a car's fuel consumption or the capacity of a hard disk drive in a computer.

Features: extra characteristics that will boost the product/service attraction to the user. For example, internet services on a phone.

Dependability: the expectation that a product will not crash within a particular time period. For example, the number of defects happening in a car within one year of use.

Conformity: the accuracy with which the product fulfils the defined standards.

Durability: quantifies the duration of any product’s life, for example, 15-25 years of the useful life of a vehicle.

Serviceable: pace with which the product can be serviced when there is a breakdown.

Appearance: this signifies an individual’s liking of the product aesthetically. For instance, the way an individual reacts to the look, feel, etc of a vehicle.

Conceived quality: it is the quality attached to a product/service on the basis of intangible measures, for example, brand reputation.

With the help of these categories, it becomes easier to identify and measure product quality.

Services are typically intangible and hard to measure. Service organisations measure quality using the categories:

Dependability: the capability to deliver a promised service reliably and accurately. For example, the actual availability of a seat after you have booked an airline ticket.

Receptiveness: readiness to assist customers to deliver quick service, the time taken to respond to a complaint and overall efficiency.

Competence: having the required skills and knowledge to deliver a service.

Courteousness: respect, friendliness, and civility of the person dealing with customers.

Integrity: the trustworthiness, reliability, and sincerity of the service provider.

Accessibility: availability and ease with which a customer can contact the service provider.

Communication: the ability to listen and acknowledge comments that are given by customers and the willingness to keep customers sufficiently informed.

These areas allow organisations to determine what should be measured in service departments. Every service organisation has to implement these features into their definite service dimensions and then choose the most suitable ones linked to their particular services, then develop a method to measure itself against its rivals.

Once the company understands what its customers want and how they perceive quality, it can learn the best approach for measuring quality and increasing customer satisfaction. Organisations can measure quality components such as the number of products being returned, the failure rate, complaints by customers, customer loyalty, and retention.

Measuring the quality of inputs, procedures, the finished product/service, and the opinions of customers, can be done by using the following steps:

Step 1: Outline the significant characteristics and their measurement

The organisation should emphasise those characteristics most associated with customer quality, and include the main problem items.

Step 2: Establish criteria for those characteristics

The standards established should correlate to the quality threshold that drives change. Standards are ineffective if they are set higher than required without improving quality.

Step 3: Control and regulate the process in order to meet the criteria

Testing each product can be costly in comparison to testing samples. Examining samples can be a useful and efficient way of finding problems in the product.

Step 4: Spotting errors at the correct time

If there are errors at the initial stages in a process that are not noticed until a more advanced stage, the work done between these stages is wasted.

Some people understand quality assurance as systematically examining the product after it is made or by quickly conforming with statements about the product on the market. However, this is not the case with Toyota. Toyota’s quality control is based on two principles: developing quality at each stage and constantly improving it. Every member of the team makes sure that only the finest work is done before the product is moved on to the next stage. If anything strange is observed, the team member can stop the process and the issue is investigated to check quality before continuing.

Step 5: Monitoring procedures in order to deliver quality

Everyday control of the processes will be useful for avoiding issues and can be caught when they occur. This will lower risk and increase profits. Once the organisation has selected quality metrics it can then plan the processes in order to fulfil the standards while being efficient at the same time.

Quality is a matter of individual preference and what comprises a satisfactory level of quality will differ from person to person.

All the characteristics of quality may not be tangible; for instance, reputation may be significant although it is difficult to measure it.

Some of the indicators for identifying product quality are performance, dependability, features, durability, etc.

Some of the indicators for identifying service quality are courteousness, accessibility, communication, etc.

Quality is ever-changing due to things such as developments in technology, improved materials, latest manufacturing methods. Therefore, no organisation can stay static as far as quality is involved.

In order to measure quality, it is important to outline characteristics, set standards, detect errors early, and monitor them.

The quality of a product can be measured by checking its:

performance, features, durability, appearance, conceived quality, etc.

Service quality can be measured by checking its competence, accessibility, dependability, etc.

Quality standards can be measured by researching and analyzing industry data.

A quality performance is measured against the set standards of quality in the industry.

What are the indicators to identify quality?

All of the above

What is the performance indicator in product quality?

Major operating characteristics of any product, are generally quantifiable, for example, consumption of fuel of a car, capacity of a hard-disk in a computer.

Can quality be measured for intangibles as well?

Some intangibles can be measured, for example, customer complaints and others can't, such as reputation. Most intangibles are built on attitudes and perceptions and therefore can be measured in different ways.

Is quality the same for all people?

Quality is very general and denotes diverse things to different people. If two individuals describe a similar product as a good quality product might not actually mean alike things.

What does the term ‘serviceable’ denote in product quality?

It is the pace with which the product can be serviced when there is a breakdown.

List the different factors that help to identify and measure the quality aspect of a product?

Performance, features, durability, dependability, durability, conformance, etc.

Already have an account? Log in

Open in AppThe first learning app that truly has everything you need to ace your exams in one place

Sign up to highlight and take notes. It’s 100% free.

Save explanations to your personalised space and access them anytime, anywhere!

Sign up with Email Sign up with AppleBy signing up, you agree to the Terms and Conditions and the Privacy Policy of StudySmarter.

Already have an account? Log in