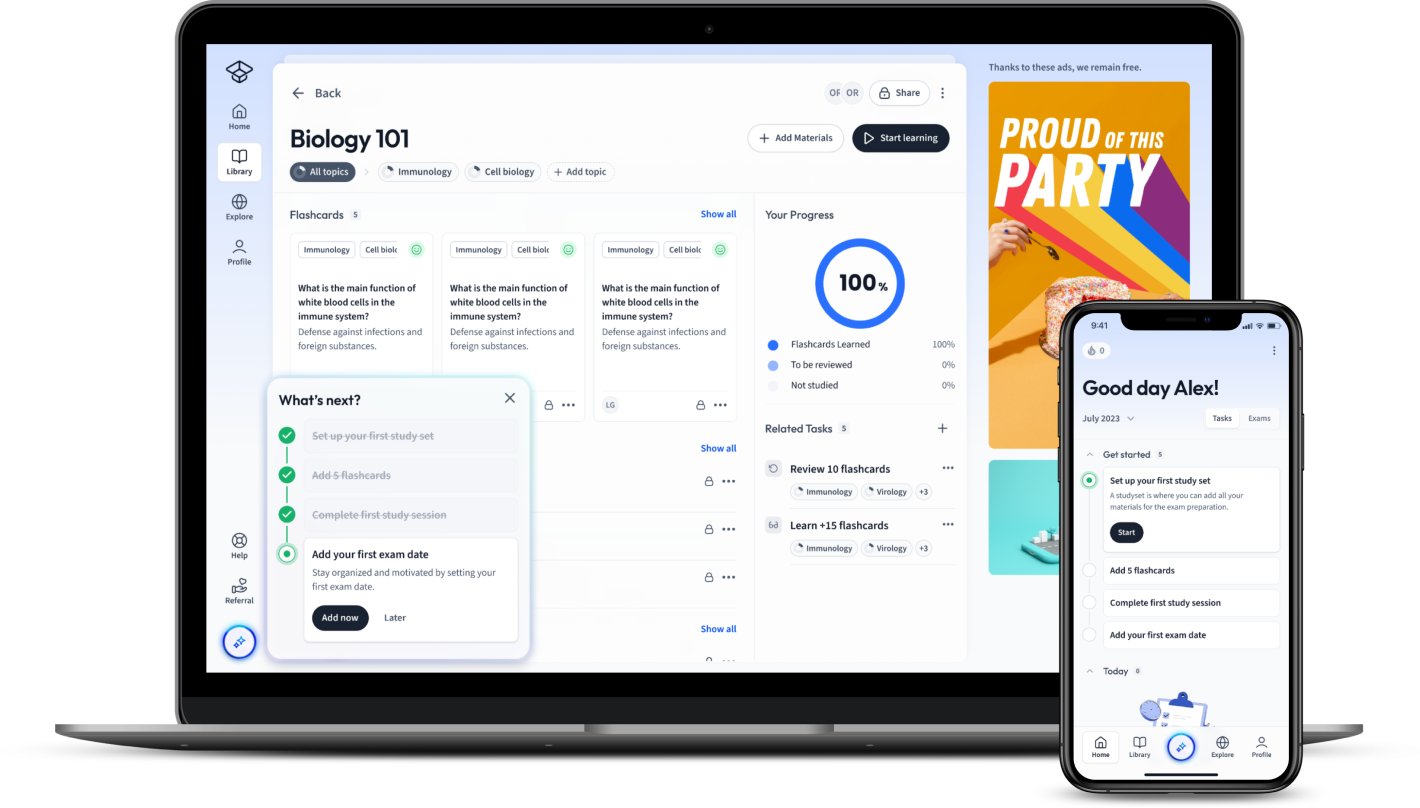

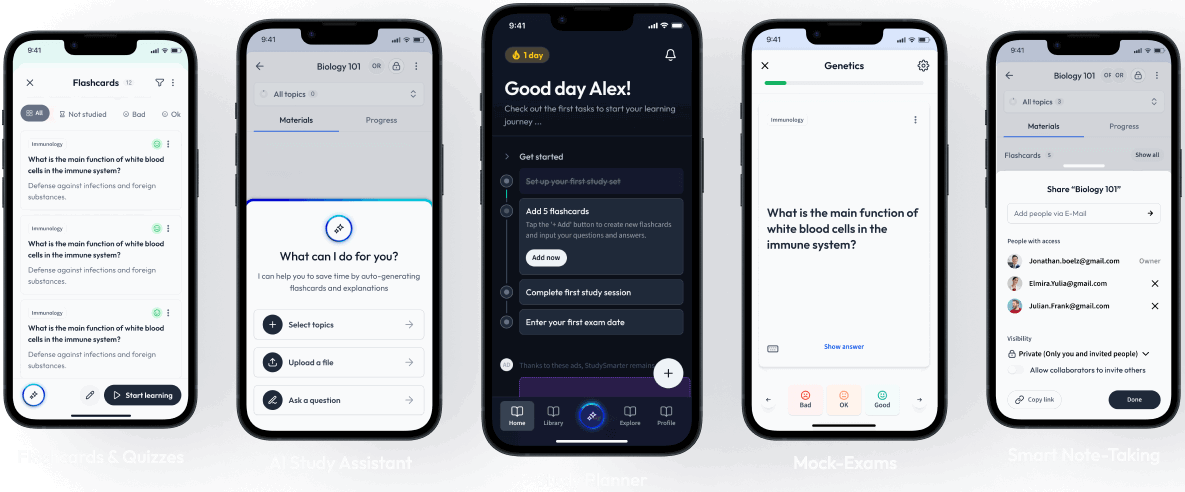

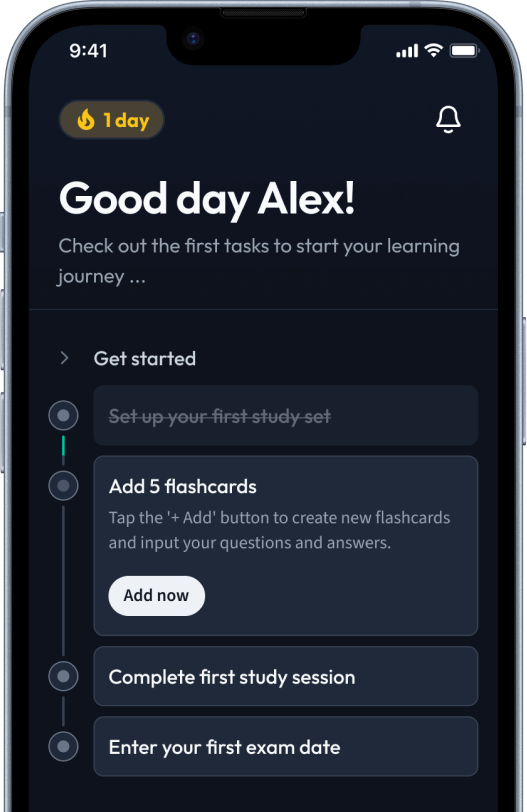

StudySmarter: Study help & AI tools

4.5 • +22k Ratings

More than 22 Million Downloads

Free

The more you hardwire a company on total quality management, the more it is going to hurt breakthrough innovation."

Lerne mit deinen Freunden und bleibe auf dem richtigen Kurs mit deinen persönlichen Lernstatistiken

Jetzt kostenlos anmeldenThe more you hardwire a company on total quality management, the more it is going to hurt breakthrough innovation."

- Vijay Govindarajan

With that being said, the implementation of total quality management (TQM) can have several advantages for a business. TQM is a process that can be integrated into a business's operations to improve overall product and service quality. Let's take a look at how organisations can use this theory to achieve overall business goals and objectives.

Total quality management (TQM) is a process that makes sure that all the work targets a mutual objective to improve product/service quality. TQM improves the manufacturing processes or processes to deliver services. Nonetheless, in TQM, the insistence remains on fact-based decision making which employs performance metrics to evaluate progress.

Total Quality Management (TQM) is a management approach that aims to optimize the quality of an organization's products and services through rigorous quality control and active involvement of employees in all aspects of the business

Healthcare organisations are aiming to grow their revenues at all levels of hospitals. The emphasis is put on TQM for the development of the system. TQM is the need for public and private hospitals in order to gain a growing percentage globally. TQM will help to lower costs, create a high level of efficiency and deliver greater quality care to its patients.

The most significant element is customer satisfaction and in healthcare customers can be crucial in several ways, to achieve a reasonable sum of profit. A healthcare organisation must review all aspects in order for its customers and the organisation itself to benefit from a higher market share.

Total quality management has profited Apple from several angles. It has aided the leadership to comprehend the requirements of the employees and satisfy their needs in the finest way. When an employee feels that they are valued as an essential pillar in an organisation and their work is acknowledged in one form or the other, they begin to contemplate ways to give back to the organisation. This was the case with Apple. Its employees are trying to give their best and contribute in the interest of the organisation.

Healthcare, Unsplash.com

In addition, another element of the use of total quality management at Apple is that it had a powerful and persuasive leader like Steve Jobs for a substantial span of time. What is needed by TQM is to have a leader who sets an example and has faith in the objectives of the organisation beyond anyone else, and Steve Jobs has led by example. Another principle of TQM promotes proper training of employees. Apple had several training programs and huge developer resources for the use of its employees. It offers training at all levels which, therefore, contributes to the quality of its workforce.

As with the majority of management procedures and practices, execution and success will differ from one organisation to another. Whilst there is no particular approved approach, the most general total quality management definitions include the following principles:

Fig. 1 - Total Quality Management principles

Fig. 1 - Total Quality Management principles

The primary focus of TQM is on the customers who buy the product/service because it is the customer who decides on the quality of the product. If a product meets the needs and works for a longer period of time than expected by the customer then they know they bought a quality product. If an organisation understands what its customers need then it will result in more sales, increasing revenues and market share.

The productivity, process, or even sales cannot be increased without the dedication from all the employees. Employees must understand the objectives of the organisation which are communicated to them. They also need to be adequately trained and provided with appropriate resources to accomplish their tasks in order to be dedicated to achieving the goals at the right time. Employees take pride and responsibility for their work and therefore increase employee retention.

Abiding by processes is crucial in quality management. Processes make sure that appropriate steps are taken at the correct time to guarantee continuity and speed up production. The advantage of the process approach is higher consistency and foreseeable outcomes and an emphasis on continuous improvement.

In a cohesive system, everyone in each department should have full insight into policies, aims, standards, and procedures. Cohesive systems support the organisation to look for continuous improvement so that it can attain an edge over its rivals.

In order to apply this principle of total quality management, an organisation should execute policies to develop products, procedures, and system improvements. An organisation should recognize and promote innovation to enhance processes. In this manner, the organisation will have more knowledge and competence to improve performance.

Everyone in the organisation should understand the objectives, strategies, and processes that will be implemented to accomplish goals. The organisation can develop an official line of communication that keeps all the employees up to date regarding the policies and changes. This will encourage the employees when they understand how they contribute in order for the organisation to accomplish its objectives.

As with most business processes, total quality management has both advantages and disadvantages. Let's take a look.

It lowers costs in the infrastructure and organisation. It assists various departments to communicate their problems and requirements with each other, in order to find a workable solution that will reduce costs in the supply chain, distribution, shipments, and other departments without lower productivity.

It helps to improve reputation for not just the product but also the organisation.

It results in better products being produced as the emphasis is on utilizing higher quality information to enhance.

Employees may think that their jobs in the organisation are at risk with the implementation of the TQM program across the board and therefore, resulting in resistance to needed change for the TQM program to work efficiently.

There is a high cost to implement the TQM program.

It may take many years for the full implementation of the program before results and advantages are seen.

TQM needs a company-wide dedication for the improvement of quality as any lack of effort will weaken the success of the TQM program.

The four phases of total quality management are planning, doing, checking, and acting.

Fig. 2 - Total Quality Management phases

Fig. 2 - Total Quality Management phases

In this stage, the employees should find the issues faced by them in the general operations and try to find the root cause of these problems. For this, detailed research is done by the employees in order to gather appropriate data, with the understanding to find answers for their problems.

In this stage, employees try to discover solutions to the problems in the first phase. Strategies are developed and implemented in order to resolve the problems being faced at work. In addition, the assessment of the effectiveness of strategies and solutions is also completed in this stage.

The performance is evaluated with the help of a comparison from the data collected before and after, for supporting the efficiency of the processes and determining the outcome.

At this stage, the documentation of the result of the process is done, and the employees prepare to face other challenges.

TQM improves the manufacturing processes or processes to deliver services.

Management procedures and practices, execution, and success will differ from one organisation to another.

Some of the practices of TQM include customer focus, the dedication of employees, approach towards the process, cohesive systems, continuous improvement, and communication.

TQM results in better products as the emphasis is on high-quality information.

TQM helps to improve the reputation of not just the product but also the organisation.

Implementation of the TQM program may make the employees less secure about their job.

Implementation of the TQM program requires a company-wide dedication.

TQM has four stages: planning, doing, checking, and acting phases.

Total quality management (TQM) is a process that makes sure that all the work targets a mutual objective to improve product/service quality.

The principles of total quality management are:

Customer focus, the dedication of employees, approach towards the process, cohesive systems, continuous improvement, and communication.

The benefits of total quality management are:

costs reduction, reputation building, and quality production.

The main focus of TQM is to keep a check on processes that improve product/service quality.

To improve total quality management, extensive research should be done to identify areas where they can improve.

What does TQM stand for?

It stands for Total quality management.

Define TQM.

Total quality management is a process that makes sure that all the work targets a mutual objective to improve product/service quality.

Is TQM used only for improving the product in an organization?

No, TQM is used for the improvement of not just the products but also for better delivery of services.

How has TQM helped Apple Inc. to improve its product?

TQM has helped the leadership comprehend the requirements of the employees and satisfy their needs in the finest way. This makes them feel like an integral part of the organization so they are motivated to deliver their best. TQM also promotes training and Apple has developed several training programs for its employees.

Why are customers one of the main focuses of TQM?

The primary focus is on the customers because they are the ones who buy the product/service and decide about the quality. If an organization understands what its customers need then it will result in more sales, increasing revenues and market share.

Why is the dedication of employees so essential for TQM?

It is important that the employees understand the objectives of the organization. The productivity, process, or even sales cannot be increased without the dedication from all the employees.

Already have an account? Log in

Open in AppThe first learning app that truly has everything you need to ace your exams in one place

Sign up to highlight and take notes. It’s 100% free.

Save explanations to your personalised space and access them anytime, anywhere!

Sign up with Email Sign up with AppleBy signing up, you agree to the Terms and Conditions and the Privacy Policy of StudySmarter.

Already have an account? Log in